System for the production of avocado seedlings cv. Hass

Persea americana

- Thematic area:

- Thematic area: Planting material and genetic breeding

- Productive system:

- Avocado

- Geographic coverage:

-

Andean region

Description

This technology includes the fundamental guidelines for producing avocado plant material, ensuring physiological, physical, sanitary quality, and genetic identity following the requirements of ICA Resolution 078006 of 2020. It contributes to improving the quality of the available planting material that allows the safe establishment of new avocado plantations in the country.

A seedling of genetic, physiological, physical, and sanitary quality is the final product of a careful process where control and monitoring of production are guaranteed. This process includes establishing and managing basic orchards to produce sexual and asexual seeds (buds) until their transport and propagation in a nursery.

The following are the different phases of the process:

1. . Basic orchards with sexual seed

The rootstock is responsible for conferring a large part of the productivity and adaptability attributes to the crown. To achieve this, the following steps must be followed sequentially:

-

Identification of suitable rootstocks for the crown.

-

Formation of basic orchards. This refers to plantations that produce sexual seed for rootstocks or buds in the case of clonal rootstock production.

-

Harvesting and transporting fruit and seed processing: the fruit must be harvested from the tree (not from the ground) at physiological maturity, that is, at the moment when the fruit can be harvested and reaches the limit of dry matter (it does not grow or gain weight), but not ripe for consumption, to maintain seed traceability. Diseased fruit or fruit with the presence of shoots must be discarded, i.e., only fruit in good sanitary conditions must be considered. Transport should be carried out in baskets, and stress factors such as high humidity, high temperature, high rooting, little air, dust, impacts, and aseptic conditions should be avoided, especially for fruit for export. The fruits must be washed, pulped (the seed testa must be removed, and the tip must be cut towards the apex to avoid mechanical impediments to the emergence of the plumule), and then disinfected.

- Germination: the seeds must be placed in a germinator or bag, with a sterile substrate and in adequate environmental conditions that allow the emergence of the radicle and plumule, as well as the easy identification of plants for discard.

The crown is responsible for the productive part of the plant and is largely influenced by the rootstock. These are usually commercial cultivars, among which cv. Hass is the most common. To obtain vegetative material with genetic identity and physiological and sanitary quality, the following must be available:

2. Basic asexual seed gardens

- Formation of the bud bank: the objective of a bud bank or clonal garden is the production of bud-bearing rods, which are used for the grafting process, according to the cultivar that is intended to be produced. Like a basic orchard, it must be marked tree by tree, and the traceability (knowing the original tree from which the fruits and buds are taken and having been characterized morpho-agronomically and molecularly) of the bud-bearing rods must be maintained throughout the process from propagation to delivery. Unlike basic orchards, in bud banks, physical separation is not required, and it is possible to have multiple cultivars in the same plot, always maintaining the identity of the material. In this sense, bud banks must be mapped to ensure that the identity is maintained by site in the event of the marking loss. The identity of the crown must be guaranteed, either by morphological parameters of the mother tree or by existing molecular markers.

- Agronomic management of bud banks: bud banks must be managed with a focus on the production of vegetative shoots and, thus, of buds, i.e., these do not focus on fruit production. In this sense, aspects such as fertilization, pruning, planting distances, and sanitary management must proceed in favor of vegetative production processes. Flower and fruit production must not be allowed there; they must be eliminated manually and with periodic checks. Bud banks must be renewed (with severe pruning, decapitation, re-grafting, or new plantings) with a frequency of about 5 years to avoid changes generated by processes such as somaclonal variations (variations that occur after repeated processes of cell duplication that occur from frequent pruning).

- Harvesting and bud transport: The apical buds that are completely healthy and that come from healthy trees with no symptoms of nutritional deficiencies must be harvested. The harvest must be done with scissors disinfected with sodium hypochlorite in a 2% solution or agricultural iodine. When moving from tree to tree, once the buds have been harvested, it is necessary to remove partially the leaves to avoid dehydration immediately. Then, these must be stored in a fridge with refrigerant, and an attempt must be made to keep the humidity of these (if possible, in airtight bags and wrapped in damp paper); likewise, they must be kept at low temperatures, 5 ° C in refrigerators, for up to three (3) days to mitigate deterioration during transport. The grafting must be done in the shortest possible time after the cutting of the buds and prior to grafting, and these must be disinfected. The traceability of the identity of the crown must always be maintained during harvest and transport.

3. Nursery management

The quality of the seeds for rootstocks and buds for crowns must be maintained during the propagation period in the nursery. This is done through the following activities:

- Substrate: it must be porous, preferably inert, with good drainage, and easy to acquire in the area. Substrates that have become widespread are coconut fiber and mixtures with perlite, peat, or rice husk; these provide the seedbed with good porosity and medium moisture retention, which are inert and easy to acquire. This substrate and its physical characteristics provide good root development and can be reused if necessary. Likewise, the substrate must be guaranteed to be sterile (without pathogens, pests, or weeds); boilers can be used at 80°C for three (3) hours for thermal sterilization. In each batch of the substrate, the electrical conductivity (less than 0.8 mS/cm), the pH (neutral to slightly acidic 5.5-6.5), and the cation exchange capacity (70 to 100 meq/100 g) must be measured, and a microbiological analysis must be performed to verify the absence of pathogens.

- Growth I: : after filling the bags (preferably inoculated with beneficial organisms such as Trichoderma sp., mycorrhizal fungi, and phosphate-solubilizing bacteria), this process begins with the transplantation of the germinated seeds (1 seed per bag, and once the plumule reaches about 2.5 cm). Nutritional and sanitary management is carried out there, as well as monitoring of the development of the rootstock prior to grafting. The bags must be isolated from the soil to avoid contamination by soil pathogens. Likewise, the rootstock must be marked by genotype in baskets with barcode labels. This process must be carried out under conditions protected by plastic, ventilation, anti-aphid mesh, doors, and storm doors that allow the disinfection of the personnel in charge. Daily monitoring must be performed to maintain a relative humidity of 60% and a temperature of 15 to 25 °C to prevent stress or pathogen-related conditions.

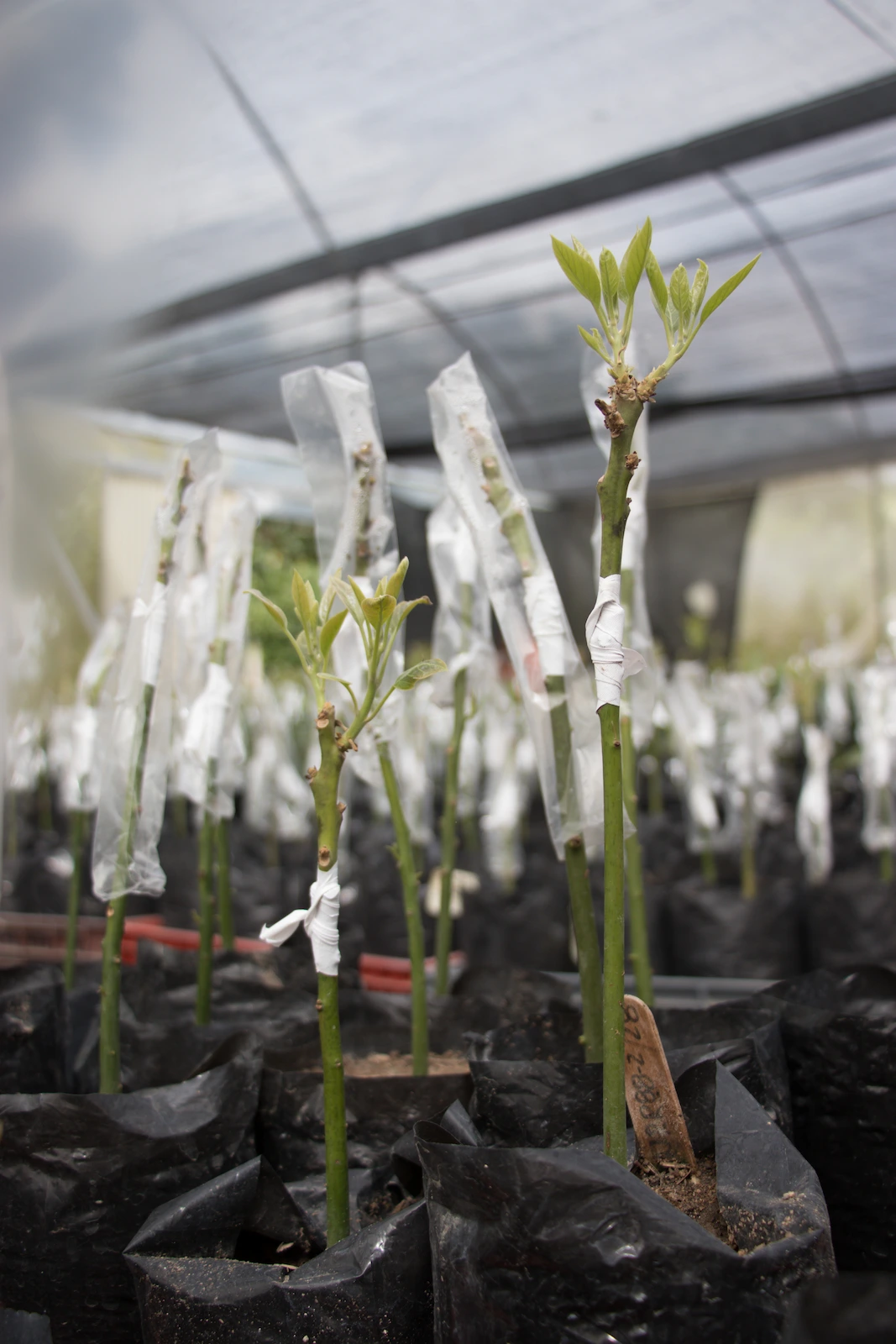

- Grafting: tthe personnel who perform this work must be highly trained, work in a completely aseptic environment, the utensils used for the cuts must be washed and disinfected before use, and the personnel must have all personal protective equipment and have washed their hands. The terminal pick technique must be used, maintaining the asepsis processes until the incision is covered; there, the perfect joint between the bevel cut and the slit must be guaranteed. Daily checks must be carried out to avoid bud dehydration, and corrective measures must be taken when necessary.

- Growth II: The final adaptation and hardening step must be gradual in terms of light, humidity, and temperature conditions to ensure the strength of the grafted plant. Physicochemical variables of the substrate, such as pH, humidity, and electrical and hydraulic conductivities, must be measured and recorded weekly. An inventory of the plants in optimal condition and those corresponding to non-compliant products must be made. Depending on the genotype, the former are usually plants with characteristics between 50 and 60 cm, with 50% of new leaf emissions and 50% of mature leaves ready to be delivered. This takes approximately 6 to 8 months. In turn, non-compliant seedlings, that is, seedlings with defects, do not meet quality requirements and should not be delivered to the customer. Sick plants, short and poorly-developed plants with defective roots or rot, and plants without new floral emissions or those emitting floral buds are discarded.

- Post-sale follow-up: it is necessary to record information on the plant material performance after delivery (with visits, calls, or other types of contact), which must be done in defined periods (for example, at the establishment and after planting at three (3), six (6), 12, and 24 months; it must have adequate and healthy growth determined by an agronomist. In the production stage, if the tree does not start production after three (3) years, it must be discarded. Finally, the productivity of the tree determines its permanence in the productive unit.

Image gallery